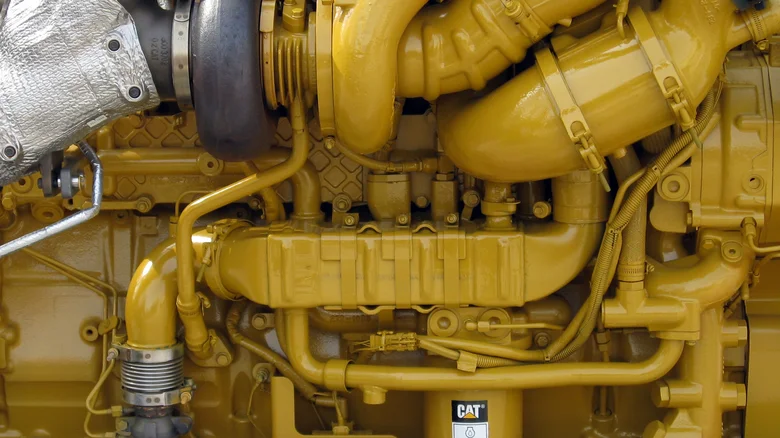

For half a century, Caterpillar Inc. has been a heavyweight of heavy machinery and industry globally. Renowned for producing some of the world’s hardest-nosed loaders, bulldozers, and tractors, the Illinois company has built a reputation for toughness and reliability. But behind earthmovers and mining equipment, Caterpillar had another profitable business — truck engines that powered some of America’s most iconic long-distance rigs on highways from sea to shining sea.

Engines like the Cat 3406E and C15 became legends of the trucking aspect, being famous for pure torque, longevity, and going a million miles with TLC. But despite popularity, Caterpillar finally closed down its on-highway truck engine manufacturing — something that took many by surprise within the industry.

So, what drove one of the biggest brands in diesel power to walk away from the trucking market it assisted in generating?

Caterpillar’s Truck Engine Heritage Traces Back to 1939

Eight decades of producing truck engines for Caterpillar started in 1939, when the company entered its first foray into this marketplace with the Caterpillar D468, a six-cylinder diesel engine that produced 90 horsepower at 1,800 RPM — humble by today’s standards, but revolutionary at the time.

This initial introduction began the long-term legacy of Caterpillar in the trucking industry. Over the years, the company released a number of other important engines, including the D312, 3408, and the wildly popular 3406E. The latter, introduced in the 1990s, was a driver and fleet operator favorite due to its power, fuel efficiency, and smooth performance.

But with the dawning of the 21st century, the landscape of diesel engines was about to change overnight — and Caterpillar found itself at a crossroads.

The Emissions Challenge That Changed Everything

By the early 2000s, governments around the world — and especially the U.S. — began implementing stricter emissions regulations to reduce emissions of NOx and particulate matter. For engine manufacturers, this meant massive investments in cleaner-burning technology in a bid to meet the 2007 and 2010 EPA standards.

Caterpillar initially responded to the challenge with its Advanced Combustion Emission Reduction Technology (ACERT) technology. This cutting-edge technology utilized a mix of precise fuel injection, advanced air management, and electronic controls to minimize emissions without compromising power.

But even with its greatness, ACERT engines began causing headaches in the real world. Truck operators reported reliability issues, maintenance nightmares, and higher operating costs, all of which smudged Caterpillar’s then-tarnished image in the trucking industry. There were even customers who sued for performance issues, further damaging the brand’s reputation with its top highway customers.

Meanwhile, competitors like Cummins, Detroit Diesel, and PACCAR were adapting faster and better to the new emission regulations. Their engines met emission regulations with fewer problems of reliability — leaving Caterpillar in a more and more vulnerable position.

Too Costly to Compete

Meeting the rapidly evolving emission standards would cost more than technical expertise — it would cost millions of dollars. Caterpillar would have needed to spend a lot on research, redesigning, and testing to keep its engines in compliance and competitive.

For a company whose business is in the construction, mining, and industrial segments, the revenues no longer justified the investment for its trucking operations. Rather than continue investing in a shrinking, regulation-based business, Caterpillar decided to strategically phase out on-highway truck engine production in 2010.

Though Caterpillar’s off-highway engines — those that drove heavy equipment, generators, and marine equipment — were still strong, driving big rigs was no longer in its plans.

The Legacy Lives On

Even though Caterpillar is no longer making on-highway truck engines, its reputation can’t be shaken. Engines like the 3406E and C15 remain legends for their strength and longevity, typically commanding high prices on the used market. Many owner-operators still rebuild and maintain these engines to this day, holding them as symbols of a generation when power and simplicity ruled the road.

In the last couple of years, Caterpillar has exerted enormous efforts in shifting its focus toward sustainable energy solutions like hybrid systems, electrically propelled machinery, and next-generation diesel technologies optimized for reduced emissions in mining and construction purposes.

Although the golden age of Caterpillar truck engines is in the past, the company’s engineering skills and genius continue to shape industries across the globe — ensuring that legends also evolve with the times.

Final Thoughts

Caterpillar’s decision to stop making truck engines wasn’t a decision based on rules alone — it was one based on survival on a strategic level. Compliance expenses, changing market dynamics, and the emergence of cleaner technology all played a role.

Today, with the trucking sector moving toward electrification and alternative fuels, Caterpillar’s pullback appears a visionary move that allowed it to focus on its core strength: building the world’s toughest machines.